NEJE Max 4 E80 laser engraver cutter 20-24W laser engraving machine Z-axis

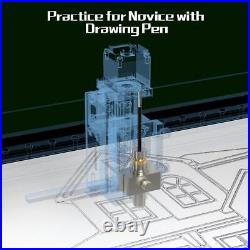

NEJE Max 4 E80 laser engraver cutter 20W laser engraving machine Electric Z-axis. WHY CHOOSE NEJE MAX 4? INDUSTRY-LEADING LARGE AREA MACHINERY QUALITY. Using higher hardness aluminum and perfect motion structure design, all structures and tracks are precision calibrated by CNC industrial mother machine, excellent vibration suppression design, innovative Y-axis belt adjuster, making the image quality and accuracy perfect. The industry's first 3-axis with lightburn an laserGRBL, freeing both hands without focusing, 3D relief, multi-layer engraving of special-shaped materials, curved surface engraving, multi-layer high-efficiency and safe cutting, supports the blade, drawing pen, metal tip to expand drawing, cutting and engraving and other functions, supports 4 axes Collaboration. RELIABLE WIRELESS CONTROL WITH LIGHTBURN / LASERGRBL / NEJE. The industry's first professional software wireless control mode for lightburn & LaserGRBL perfectly solves the reliability of wireless connections and prevents data packet loss from connection interruptions. The OTA software & firmware are permanently upgraded and support APP wireless connection creation. The standard pen head provides a safe practice tool for novices. The NEJE laser has extremely small cutting volume and multi-layer high-efficiency cutting mode to avoid the risk of fire caused by talking materials. The reliable control system with 10 years of iteration ensures stable operation. It has built-in MEMS vibration protection, emergency stop expansion, flame Detection expansion, safety door expansion and other functions. The laser is equipped with a protective hood to reduce light radiation spillage, and the automatic smoke exhaust control and protective box body can efficiently discharge exhaust gas. FREE TUTORIALS AND PROFESSIONAL SERVICE SUPPORT. NEJE Project Idea: Latest project cases and document sharing. NEJE Facebook Group: Learn and grow with top artists.

NEJE Forum: NEJE professional after-sales support. NEJE equipment installation\usage instructions and maintenance guidance. BENEFITS OF MOTORIZED Z AXIS.

By optimizing the focus size of E80 and controlling the cutting amount of each layer, it maximized the efficiency of each path in E80. The cutting and engraving efficiency is increased by 200%, which is higher than that of 40W (optical power) module. The optical design of NEJE E80 makes focus power density of E80 and beam angle reach a perfect state by optimizing the beam structure and adopting more complex manufacturing technology. When the power is 1 time smaller than the 40W module, it can even reach the same cutting speed, and the cutting notch is smaller, avoiding the trapezoidal notch and XY asymmetry problems. The repositioning accuracy of the motorized Z-axis reset sensor reaches 0.001mm, which provides more precise focus control for materials with high focus accuracy requirements such as engraving metal. It is more expressive when engraving multi color on stainless steel surfaces. Combining excellent NEJE modules, E40, A40640, and E80 modules makes it easier to achieve grayscale effects on surfaces. NEJE Max 4 has higher productivity with functions such as larger area and preset focus motorized Z axis.When you need to create multiple different projects, you can preset Z offset for each layer to complete all projects together. Combined with NEJE's unique offline running function, you can directly import files into the device, making it create your projects safely and automatically without occupying your computer and time. The new and innovative design of the motorized Z-axis greatly improves the safety and controllability of high-power modules. You can preset the focus position on each layer in the lightburn software. From then on, you only need to place the material on the honeycomb platform without focusing, completely releasing your hands.

Take advantages of motorized z-axis for multi-layer engraving to achieve various 3D effects. Combined with NEJE's unique multi-layer independent controlled gas assist function, it can even engrave high-quality 3D art works on materials such as stone and hardwood. Compared to traditional CNC milling, the production of 3D relief with E80 module can present more details and it's more efficient. They found it when they got engaged. He find me at a craft fair and I had 5 days to figure it out before the wedding.

Had to do it in many segments since it was not at all flat. When engraving irregular materials (such as driftwood, natural stone), we can use the motorized Z-axis multi-layer control function and repositioning function to achieve 3D space multi-layer engraving and cutting, making diverse artistic creation for irregular materials.

CURVED SURFACE ENGRAVING & CUTTING. Through surface modeling like in Fusion 360, we can achieve CNC path like working modes through real-time Z-axis linkage, directly processing surface works. In most projects, we can only use the rotation axis to control the conventional cylindrical structure.

Most irregular surface projects cannot be carved or cut, resulting in more advanced needs. How can we more accurately carve irregular surfaces? Therefore, surface modeling has become a direction for our exploration, and the NEJE team will also take the lead in exploring more possibilities in this direction.

DRAWING PEN / BLADE FOR GRAPHIC AND TRANSFER VINYL ART. With blade, heat transfer vinyl and foam within 1mm can be cut easily with Lightburn. The NEJE Max 4 Z-axis sensor has a 0.001mm reset repetitive positioning accuracy and a precise CNC support platform to support blade projects. NEJE provides blade and cutting pads for auxiliary cutting. NEJE PROVIDES BLADE AND CUTTING PADS FOR AUXILIARY CUTTING. 17MM PINE BOARD, 300MM/MIN FROM 2 PASS, HIGH VERTICALITY. 0.15MM STAINLESS STEEL PLATE, 250MM/MIN FROM 1 PASS. 5MM MDF, 200MM/MIN FROM 1 PASS.10MM BLACK ACRYLIC, 180MM/MIN FROM 1 PASS. 10MM CHERRY WOOD, 250MM/MIN FROM 1 PASS. 12MM BASSWOOD, 180MM/MIN FROM 1 PASS. 30MM PINE WOOD, 200MM/MIN FROM 5 PASS.

30MM BLACK ACRYLIC, 100MM/MIN FROM 5 PASS. Matrix optical compression technology makes the focal point of NEJE E80 0.06x0.06mm, the symmetrical XY shape make it achieve the ultimate in engraving and cutting performance and the power density reaches 6666W/mm², Compared with other 40W(output) module, power density:1777W/mm²(0.15x0.15mm, 8xLD, Current highest power), the performance of E80 is higher than the 40W module. Due to the extremely strong power density and optical design (symmetrical XY shape), NEJE E80 has more excellent performance. With such high energy performance, the NEJE E80 module has almost achieved the mechanical performance of belt drive to its limit. When engraving on canvas, a speed of 400mm/s is quite normal.

The entire structure of NEJE Max 4 has been calibrated by the industrial mother machine. It is not an ordinary DIY assembly. The repeatable positioning accuracy and motion control accuracy of the X, Y, and Z axes reach 0.01mm, and the repeatable positioning accuracy of Homing reset reaches 0.01mm. After the new firmware upgrade, the NEJE Max 4 industrial linear rail has very powerful scanning efficiency. NEJE engineers have improved the instruction operation efficiency and execution efficiency to the ultimate performance by optimizing the traditional GRBL firmware. SPECIFICATION - NEJE MAX 4. Frame Size (L - W - H): 970x582x60mm Working Area(X - Y): 750 x 460mm, Extends to 750x1030mm(about 29.5x40.5 inch) X axis:Industrial straight track, bottom CNC straight line correction Y axis:NEJE diamond CNC linear track, smooth and durable Z axis:Industrial linear track A axis:Rotary axis expansion Y axis Extension: Yes, NEJE will provide linear extension track, and the Y axis can be extended to 1030mm. Limit Switch: Build in X Y Z Homing Repeat Position Accuracy: 0.01mm Repeat Position Accuracy: X Y: 0.01mm; Z: 0.001mm Recommended acceleration and top speed: 400mm/s NEJE Max 4 has a longer acceleration stroke, and the peak speed is faster than the ordinary 400x400mm frame. Vertical Carving: Yes(90°) Accuracy: 338dpi Pixel: 6133 x 10000 px Input Voltage: 12V or 24V, Match according to module voltage Interface: 5.52.1, Max 6A Compatible: all 12V and 24V NEJE modules M7, M8, Door Extension: Yes Lightburn Offline Control: Yes Lasergrbl Offline Control:Yes BLE Bluetooth Function:Support Bluetooth 4, Windows 10, iOS 8 and Android 4.2 and above. App control: Yes MEMS protection: Yes NEJE Software OTA Upgrade: Yes Software: NEJE Win Soft, NEJE APP, Lightburn, LaserGRBL Firmware: build in NEJE fireware and GRBL 1.1f(optimized) Systems Support: Win 7/Win 8/Win 10, Android, iOS, ipadOS, macOS File Format Supports: GC/SVG/DXF/JPG/JPEG/PNG/BMP/TIF/etc. 0.030.04mm fixed focus.0.060.06mm fixed focus. It has a wide range of comprehensive applications and can be widely used for carving various materials, including wood, metal, stone, glass, and has universal cutting ability A40640 has a very wide user base and is the inventor of the Diode Laser high-power module. The classic is still in use today.

Having very fine carving and cutting expression abilities, for users with higher requirements for precision, such as ceramic carving, leather, MDF cutting within 4mm, etc. Powerful power and perfect optical quality, with an ultra long lifespan design, the E80 has higher commercial applications in carving and cutting efficiency. It will be a standard grade product for Diode Laser entering the industrial era.Thickness:0.05 mm 300 mm/min. Thickness:0.1 mm 300 mm/min. UNIQUE DESIGN OF NEJE MAX 4. The X-axis adopts a hardened and thickened CNC calibrated linear groove laid with linear rails.

The durable scanning ability and reliable smoothness of the X-axis are optimized to the extreme. Achieving lightweight while maximizing scanning performance. Achieve stable and perfect image quality within the 400mm/s range. The Y-axis adopts a dual motor design, calibrated with a linear track to eliminate long dimensional travel tolerances.

The torque and stability of the stepper motor have been improved. This enables the machine to accurately and efficiently control the laser module for long-distance movement. The stable dual motor design can even allow the machine to work vertically and adapt to more usage scenarios.The NEJE Max 4 machine has industrial-grade structural accuracy. All parts are calibrated by high-precision industrial master machine. Linear trajectory correction has been applied, and the installation direction of each plane is accurately matched, making the operation of the module more accurate and stable. X, Y, and Z axis are equipped with limit switches, the repositioning accuracy after homing for X, Y axis is 0.01mm, Z axis: 0.001mm.

Both the X-axis and Y-axis are equipped with belt tension adjusters, and the roller shaft adopts an eccentric nut design with adjustable tension, ensuring the accuracy of image drawing. We will reply you ASAP. How we got our start? Since the establishment of NEJE in 2013, we have a very professional team, labs and factories to support the operation chain cooperation system. Serving over 1 million users in the world with 5 stars customer feedback so far.What makes our product unique? The only engraving module that has been fully developed and manufactured independently. The engineering team at Mechanical and Software APP provides the most advanced experience in laser process technology and excellent software. Why we love what we do? Our mission is to invent production technology and connect it with handmade producers, for the goal of higher productivity, accuracy, and more suitable for the future.

Making the best, most affordable tools available. And if we get to have more fun discovering in latest products, all the better. NEJE Max 4 A40640 laser cutter 4 Axis Industrial Laser Engraving Machine 12W. NEJE 3 MAX V2 E80 laser engraver & cutter laser engraving machine +extension kit.

NEJE Max 4 E40 Laser engraver cutter 4 Axis Laser engraving machine 11W. NEJE Max 4 A40640 Laser Engraver cutter 10W laser engraving machine Fixed focus. NEJE 3 N30820 Laser Engraving Cutter Machine Engraver Printer DIY 5.5W 170X 170.