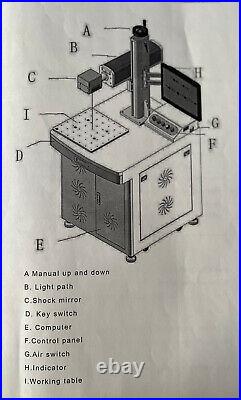

Fiber Laser Engraving Marking Machine

1.1 Mechanism of laser marking. Laser has the characteristics of high brightness, high directivity, high monochchromaticity, and high coherence. It is incomparable with the ordinary lighting source.

After through focused laser beam, the focus can produce thousands or even tens of thousands of degrees of high temperature, so that it is possible processing almost all of the materials. Laser marking is carved permanent marker with laser beam in different kinds of material surface. The effect of marking is through the evaporation of surface material to show deep material or with the result of the surface material chemical physical change and "carved out" by light effect, Shows the etching of graphics and text. 2 The characteristic of the laser marking.Can process for a variety of metals, non-metallic materials. Especially for high hardness, high melting point, brittle materials are marked more advantage. Belong to the non-contact processing, no damage to the product, no tool wear, tags are of good quality. The laser beam is very fine, the consumption of Processing materials is very small, the heat-affected-zone is also small. The Processing efficiency is high, can use the computer control, easy to realize automation.

Not easy to be fake. 3 The description of the production. Laser marking machine is the collection of laser, computer, automatic control, precision machinery technology of high-tech products. The marking machine adopts the galvanometer scanning system, with.

Fast Speed, high precision, can work long hours. Able to use in most of metal materials and some non-metallic materials such as: were carved silicone, rubber, epoxy, ceramic, marble and other materials difficult to imitate or make permanent security tags. Our company provides special marking software based on Windows platform. The content of the marking can be text, graphics, images, serial number, bar code and their combination and can be directly in the special marking software input, edit, or by an AutoCAD or Coreldraw, adobe Photoshop graphics editing software, By computer control input and output. Tag content repeatable carving, laser marking for non-contact processing, no pollution, small impact on workpiece physical properties, especially suitable for processing hard hard, soft, brittle materials. The design of the marking machine is Comply with international safety and operating standards. Any product defects and faults manufacturing reasons when the Customers receive the product within a year. Laser marking machine is adopted by Class 4 lasers, which is the most advanced lasers, such as improper use will harm the human body, the user of this manual should be required to take protective measures.