EFR 130W-160W Laser Engraver Cutter Laser Engraving Cutting Machine 1300x900mm

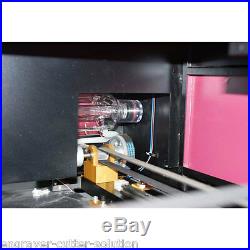

US Stock, 51" x 35" 1390 Luxury Laser Engraving and Cutter, with EFR F6 130W-160W Laser Tube. 51" x 35" (1300mm x 900mm). EFR F6 CO2 glass laser tube 130W-160W (Normal lifespan: about 10000 working hours). 15.7 (400mm) / s (Adjustable).

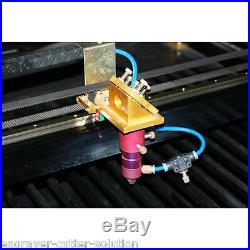

Water cooling and protection system. BMP, PLT, compatible with many file formats for Windows OS, such as AI, CorelDraw, Photoshop, AutoCAD, etc. Lasercut 5.3 engraving software. High precision equilibrium linear guide ensures the precise processing effect.Adopt the super fine cutting technology, which has features of extensive material processing. Smooth cutting edge and burr - free. Original Singapore imported lens with molybdenum base, making the equipment produce smaller facula and.

Exhausting, absorbing and assistant blowing systems solve the problem that troubles the laser equipments manufacturing industry for years. Laser cutter is equipped with aluminum strip shape platform. This machine uses USB port to transmit data, it is equipped with large internal memory capacity.

Adopts high quality EFR CO2 glass laser tube made in Germany. It can make delicate and complicated designs on acrylic, wood and PVC and so on. Avoid polishing, processing high speed, and high precision. Glass viewing windows creating a safe enclosure for laser processing. Original Singapore imported lens can greatly improve working efficiency and reduce cost.Exhausting, absorbing and assistant blowing systems extend the life of the laser tube. Aluminum strip shape platform can bear heavier materials, such as acrylic, wood and much more non metal materials. Large internal memory capacity improves the working speed with greater efficiency.

With a fine cutting effect and price advantage. This high precision laser cutting machine can make delicate and complicated designs on acrylic, wood and PVC and so on for the advertisement, handicraft industries etc. Servo motor is optional in high - end applications.51" x 35" (1300mm x 900mm) working area. Up to 23.6 IPS (600mm/s) high working speed. Pass-through front and rear doors to accommodate long work pieces.

Three unique protection functions, i. Anti-interference function, water - protective function and power cut - off function ensure longer working life, safety and effectiveness. Equipped with high quality W. Ater chiller cw5200, which can prolong the lifespan of the laser tube and ensure a better engraving effect. Working Area: 51" x 35" (1300mm x 900mm) Max.

Cutting Speed: 15.7 (400mm) / s Max. Engraving Speed: 23.6 (600mm) / s Laser Power: EFR F6 CO2 glass laser tube 130W-160W (Normal lifespan: about 10000 working hours) Max. Cutting Thickness (Acrylic): 1.2 (30mm) Resolution Ratio: 0.0064mm Min. Shaping Character: Chinese Character: 0.1" x 0.1" (2mm x 2mm), letter: 1mm x 1mm Location Precision: <0.01mm Power Supply: AC110V±10%, 60HZ Gross Power: <1250W.Instructions of Laser Engraving Cutting Software There are three kinds of RD laser cutting software. One is the direct output software based on CorelDraw (hereinafter referred to as CorelDraw_Laser); the other is based on the direct output software based on AutoCAD (hereinafter referred to as AutoCAD_Laser). In addition, there is another kind of independent software (hereinafter referred to as LaserWork), which is more simple to use in the first stage of using laser cutting machines. Parts quality guaranteed: The main board and power supply of laser cutting machine were put into an oven at temperature of 50 degree for an aging test, minimally 4 hours.

Laser head: Enclosed, with air blowing device, which is safer than unclosed head. Laser Test Each laser tube and its power source shall be tested for 8 hours on/off power test: There are strict inspection criterions for its light beam quality and laser power. Guide rail: High precision equilibrium linear guide rail imported from Korea.

Each guide rail shall be tested before installation. 100% Check of Materials We perform 100% check to all the parts of laser cutting machine in order to avoid any disqualified parts coming into the next step of work. Test of Main Board & Power Supply Put the main board and power supply of laser cutting machine into an oven at temperature of 50 degree for an aging test, minimally 4 hours. Test of Transmission Parts Check the synchronizing wheel and bearing of the.

Whether are concentric and easy in rotation as well as its deviation whether is less or equal to 0.02mm. Processing Crotrol During the production of laser engraving machines, our quality inspector will patrol and check its installation quality. It is mainly to check the parts of mechanics and electrics, cables whether satisfy the requirements of installation blueprint. If any error or problem found, the correction treatment will be executed immediately. Test of Guideway and Rectangular Tube Mainly to test the flatness, linearity and torsion resistance of t the guideway and rectangular tube.

Put the rectangular tube and the guideway onto a marble platform, then use dial gage calibrator to check: the tolerance bigger than 0.05mm/m is disqualified. Stretching Force Tester for the Belt of Laser Cutting Machine Ensure the machine platform cutting in consistency. Collimator Test The test method for the linearity, flatness and verticality of the laser cutting machines guideway is to use Auto Pricise Collimator 1401 Double-way. Handy Power Indicator of Laser Cutting Machine Any point of the laser cutting machines power test, ensure the laser cutting machine to give best cutting effect. Electromagnetic Oscillograph of Laser Cutting Machine To test the electromagnetic interference and ensure the running stability of laser cutting machine.

Please download the PDF file of User Manual of LCM-BY-Z Series Laser machine to learn more! Machine Installation Include: Laser tube assembly; Water Chiller installation; Air pump connection; Exhaust fan installation; Grounding wire connection.

Software and USB driver Installation III. Software Operation Edit the images in the engraving software or input the color pictures into the engraving software, edit it, and then set the processing parameters, output images to our laser cutting machine, finish the work. Lead Time: After receiving customer's deposit, within 3 - 5 days. Wooden Box: There is total one wooden box.70" x 71" x 43 (1765mm x 1810mm x 1100mm). 79" x 62" x 51 (2030mm x 1570mm x 1300mm). We would post the new parts with step by step instructions in PDF format on how to replace the parts to you. We offer 14 days 100% satisfaction guarantee on all our machines. If you are not satisfied after receiving an item.

The item "EFR 130W-160W Laser Engraver Cutter Laser Engraving Cutting Machine 1300x900mm" is in sale since Wednesday, December 27, 2017. This item is in the category "Business & Industrial\Printing & Graphic Arts\Screen & Specialty Printing\Engraving". The seller is "engraver-cutter-solution" and is located in Rowland Heights, California. This item can be shipped worldwide.

- Featured Refinements: Laser Engraver

- Model: LCM-BY-Z1390-150W-US

- Modified Item: No

- MPN: 0025001468000

- Custom Bundle: No

- Brand: VING

- Non-Domestic Product: No

- Maximum Cutting Area: 51" x 35" (1300mm x 900mm)

- Cutting Speed: 15.7" (400mm) / s (Adjustable)

- Maximum Cutting Thickness: 1.2" (30mm) (Acrylic)

- Power: 1250W

- Cooling Method: CW5200 Water cooling and protection system

- Interface: U disk, enternet

- Voltage: AC110V - 240V, 50Hz

- Certificate: FDA & CE

- Warranty: 2 Years

- Laser Power: EFR F6 130W-160W

- Supported Image Formats: BMP, PLT, AI, CorelDraw, Photoshop, AutoCAD, etc.

- Cutting Software: Lasercut 5.3 engraving software