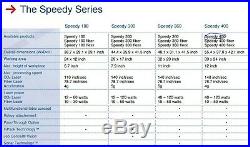

Trotec speedy 400 Professional CO2 Laser Engraver 80 Watt (USED, 2017)

TROTEC SPEEDY 400 LASER ENGRAVER (80 WATT, CO2 Laser) FASTEST LASER FLATBED LASER ENGRAVER ON THE MARKET. WORK AREA: 40 x 24 INCHES. WORK PIECE HEIGHT: 12 INCH.

LASER POWER - CO2: 80 Watt. INCLUDED TABLE: BLACK ALUMINUM GRID TABLE.

INCLUDED EXHAUST FAN: 2HP 220v. INCLUDES PASS THROUGH SLOT FOR ENGRAVING ITEMS LARGER THAN THE WORK AREA.

Please see below for details and other information. This laser was used in a professional shop in Columbus, OH for about 12 months. The laser than was used in a home workshop with very light use for about a year. Any additional questions please let me know.

The Machine is in great condition and is the best laser we have ever owned, very little maintenance or fuss required, a true plug and play CO2 Cutter / Engraver. Trotec Speedy 400 CO2 Laser (80 Watt).

40x24 Aluminum Cutting Grid Table. Trotec Software Suite JobControl Laser Software (works with CorelDraw, photoshop, autocad, illustrator, inkscape, Microsoft Word, etc). With pump for air assist.

Description: 8223 BLACK ALUMINUM GRID TABLE. Description: 8023 GAS KIT INNKL. Fastest laser machine on the market.

Speedy is the fastest laser engraver on the market. With an engraving speed of 4.2 m/s and an acceleration of 5g, it outperforms its competitors. This is made possible by two real innovations from the Trotec development team: an innovative motion system and a revolutionary drive concept.

What does that mean for you? Most efficient production, highest throughput and thus maximum profit with impeccable quality. Six times faster cutting with OptiMotion. The new Speedy 400 is up to six times faster when cutting than comparable laser machines on the market.

Using OptiMotion the cutting speed and acceleration are calculated and optimized in real time based on the geometry. This is standard for larger cutting systems, but for medium-sized engraving it is a true innovation. OptiMotion delivers high quality in curves and maximum throughput. Tests with competitor devices have shown that cutting jobs can be completed up to six times faster thanks to OptiMotion. Trotec laser electronics sets new standards.

Calculations are so high-performance that planning the path can be perfectly done in real time using the digital twin concept - a digital replica of the machine in the laser electronics. This yields the physical maximum from both machine and application. OptiMotion automatically searches for optimal speed parameters.

In other words: The operator only needs to determine the power and speed required for laser cutting - regardless of the cutting geometry. When processing the job, OptiMotion regulates the speed and acceleration in real time depending on the geometry.

For the operator, valuable time can be saved in laser file preparation. Longer service life, less maintenance. Clean laser machine for perfect engraving results. The cleanliness of the laser machine during laser engraving is not a question of aesthetics, but rather a factor in perfect function. Soiling of the lenses, mirrors, or electronics may result in premature breaking or failure.Dust on motors or axes will have a negative effect on the engraving result. Trotec lasers have been designed to protect sensitive components against dust. The lens, the mirrors, electronics, motors and axes are mounted in a manner to prevent any contact with dust and debris.

Dust protection for higher productivity. InPack Technology provides optimal protection for all these components.This is why Trotec laser machines operate with virtually no maintenance or cleaning requirements, even for most intensive use. This means higher productivity and lower lifetime operating costs. The right working table for every application. The multifunctional table concept allows optimal configuration for all engraving and cutting applications.

Depending on the application the ideal table can be selected and changed easily and quickly for highest processing quality and productivity. For example, foils or paper require a vacuum table with high exhaust power levels in order to achieve optimum results. When cutting acrylics, however, as few contact points as possible are desirable, in order to avoid back reflections. In this case an acrylic cutting grid or acrylic slat cutting table would be suitable. Aluminum Cutting Grid Table (INCLUDED WITH THIS LISTING).

This cutting table is the perfect solution for all general cutting tasks. It is suitable for a variety of cutting tasks with parts smaller than 100 mm, as these remain in a flat position after the cut.

The table has more support points compared to the aluminum slat cutting table. Reliability, high engraving quality and longevity.

Trotec laser systems are equipped with a new line of CO. The innovative and patented laser source concept stands for reliability, high engraving quality and longevity. The resonator body where the laser radiation is generated is made of 100% ceramic. Usually all-metal, and sometimes glass laser sources are used for laser processing.

Technology totally redefines the basic laser source. The ceramic design gives tremendous benefits compared to all metal or glass lasers. There are no aluminum welds or sealings, which could leak over time.

This is guaranteed by the production process. Two ceramic half shells are fused together to form the resonator during manufacturing. The ceramic resonator is fired at 800 degrees and the burning process effectively cleans the interior surface immaculately. All of the optical elements are glued onto the ceramic, the electrodes are mounted on the outside of the resonator and the gas is excited through the ceramic body. This means that there are no interior metal surfaces that could damage the gas mixture's equilibrium.

The result is a pure gas composition over the whole lifetime of the laser source. Fastest pulse speeds for highest engraving quality.

Ceramic lasers can be operated at much greater pressures resulting in faster pulse speeds, which in turn are critical for high speed engraving and marking applications. Laser users can benefit from highest engraving quality. Also, the electronics' innovative architecture features a lower energy consumption. Benchmark tests show a reduction of up to 30%.The laser sources have been perfectly optimized for Trotec laser systems to maximize the CeramiCore. Iradions research efforts are fully focused on their groundbreaking ceramic technology.

Initially developed for one of the worlds biggest defense and security corporations, Iradions laser source technology was designed to provide precision, stability and longevity in the harshest environments possible. Focus modes for precise laser engraving and cutting.

The focus setting on your laser engraver is an important factor for achieving optimal engraving results. The focus setting refers to the distance between the head of your laser machine and the material you are engraving. Trotec offers different focus modes for different applications. Is an "automatic" focus mode that does not require you to use a focus tool. Instead, you press the Z-positioning keys on your laser engraver, and an ultrasonic sensor on the laser head detects the surface of your work piece.The focal point is calculated automatically and the Z-axis of the laser engraver moves in the appropriate position. Provides the highest level of accuracy for focusing on every position of the working table. This highly accurate focus mode makes it easy to use the correct focus mode on your laser engraving machine every time. In addition, it is possible to focus the laser using an integrated light bar focus, the material thickness or manually using focus tools. If you are working with flat, opaque items or materials of unknown thickness, the Light Bar Focus is ideal.

This mode works by using sensors (light barriers) that are installed laterally in the enclosure. You enable this focus mode on the keyboard of your laser engraving machine, which causes the processing table to automatically move up until the sensors detect the engraving material and calculates the correct focal point. JobControl Software includes a feature that calculates the optimal focus point when you enter the material thickness and the lens used. The software, which has a "bi-directional connection" with the laser engraving machine, senses the exact height the work table.

Once you enter the information in the software, the table moves to the correct position with only one press of the button. This is an ideal focus mode for processing materials with known thickness. Each focus tool ist pre-set to the focal length of the corresponding lense and is appropriately colour coded.The operator simply hangs the focus tool on the laser head, and then moves the working table manually until the surface of the workpiece to be engraved touches the focus tool. Now the right focus point is set. This focus mode is fast and flexible.

This method is especially useful when you work with a lot of different materials, if the material thickness is unknown or can not be measured and for cylindrical objects. Best accessibility and inside view. Unlike some lasers on the market, the Speedy 360 and Speedy 400 were designed without the front bar or struts to provide easy and ergonomic access to the work area. This ergonomic design makes loading and unloading (especially large or heavy parts or a rotary attachment) much easier.

It also minimizes the physical effort required from the operator, because loading and unloading the laser machine is done at hip height, and the front cover can be folded down completely to minimize back strain on operators when they are inserting working tables or materials. Trotec laser machines are equipped with a transparent top cover, allowing you to monitor your laser engraving job at any time during processing and no matter where your workpiece is positioned without lifting the lid.

The transparent top cover provides a view the entire cabinet of the laser machine. The design also includes LED lighting, which illuminates the entire working area. This convenient feature improves operator comfort and convenience. With the new dynamic status display, the status of the laser and the processing progress are visible directly on the machine. This makes it easy to see at a glance whether the laser is switched on, a job has been completed or stopped, which laser source is activated, etc.

The following statuses are displayed. Job progress in % sections. Or fiber laser source activated. The item "Trotec speedy 400 Professional CO2 Laser Engraver 80 Watt (USED, 2017)" is in sale since Wednesday, May 29, 2019. This item is in the category "Business & Industrial\Printing & Graphic Arts\Screen & Specialty Printing\Engraving". The seller is "psc-wy" and is located in Delaware, Ohio. This item can be shipped to United States.- Laser Type: CO2

- Model: SPEEDY 400

- Country/Region of Manufacture: United States

- Engraving Method: Laser

- MPN: 60915

- Brand: Trotec